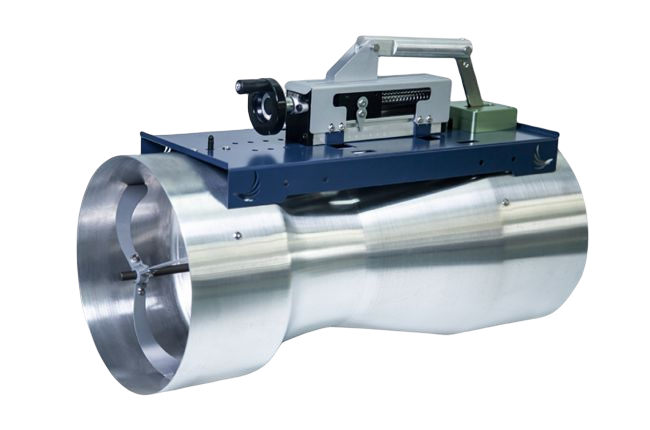

The combination of mechanical pressure independent regulator and high-speed air flow controller extends the air flow control to the highest level

The rapid positioning of servo drive and the rapid change of pressure in the pipeline ensure the stability of the overall system

View details

Ultra quiet operation of the driver and valve body

View details

Perfect combination of CFD simulation and structural mechanics

View details

| Function /option | Constant air volume(CAV) | Electric variable air volume(VAV) |

|---|---|---|

| Control type | Mechanical | Servo motor |

| Flow feedback signal | —— | √ |

| Power loss protection (normally closed or normally open) | Fixed position | Normally open/ normally closed |

| Continuous operation with power outage | —— | Standard |

| Valve body factory insulation | Option | √ |

| On-site flow adjustment | Option | √ |

| Flow alarm via sensor | —— | Option |

| Flow alarm through pressure switch | Option | Option |

| All valves include pressure independent devices, factory calibrated adjustable positioning devices, providing flow ranges from 64-27600m³/h. | ||