BOM module design, easy to disassemble and assemble, and the processing air volume is 1000~100000m3/h.

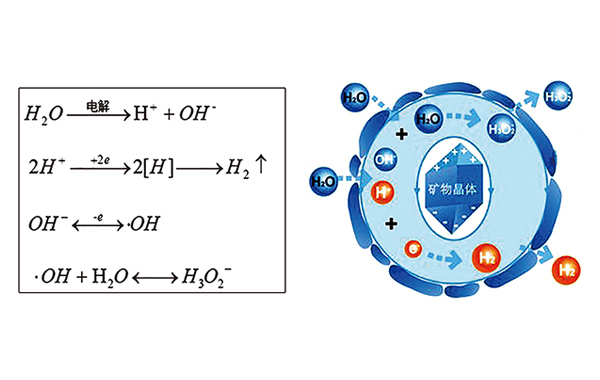

There is a class of materials in the world that are naturally electrically conductive, but these substances are not activated in polarity and cannot exhibit their electrical energy characteristics in the natural state. Using scientific formula and special processing, it can fully exert its electric energy effect, so that countless micro-electric fields can be formed around its material.

At present, the special process adopted by our company has processed the particle size of the material to nano-scale, d50=100nm, which can increase the energy level of the material and the number of micro-electrodes hundreds of times, and cause the surrounding water molecules to undergo micro-electrolysis. Positively charged hydrogen ions (H+) and negatively charged hydroxyl groups, namely hydroxyl groups (·OH). The two hydrogen ions (H+) become hydrogen gas (H2↑) after being supplemented by electrons at the negative electrode of the microelectrode. The remaining hydroxyl groups (·OH) will play an important role in purifying the exhaust gas.

The water molecules needed to purify the exhaust gas can be supplemented in the pretreatment section, and after passing through the WELL+ nano-micro electrolytic material, a large number of hydroxyl groups are generated. It can effectively decompose various organic pollutants through its strong oxidation.

After a multi-step reaction, carbon dioxide and water are finally produced

C6H6+OH=C6H5+H2O

C6H5+OH=C6H4+H2O

In this way, one H is replaced each time, and nitrogen oxides and water are finally generated through multiple steps.

Decomposition CH3CCI3(trichloromethane)

CH3CCI3+OH=CH2CCI3

......Generation of CO, HCL and H after multiple steps2O

H2S+●OH=HS+H2O

HS+●OH=S+H2O

S+●OH=HSO2+H2O

NH3+OH=NH2+H2O

NH2+OH=HNO+H2↑

NH2+OH=NH+H2O

2NH+O2=2HNO

HNO+O2=HNO3

HNO+OH=NO+H2O

NO+NH2=N2+H2O

After a multi-step reaction,

Finally nitrogen and water are produced.

The purification technology of WELL+ nano-electrolytic material includes not only the generation of hydroxyl groups by electrochemical action, the chemical decomposition of hydroxyl groups, but also physical adsorption. The microporous adsorbent material in the ceramsite filler, the nano-scale micro-pores between the nano-scale particles, and a large number of micro-electrodes make it highly adsorbable and can effectively capture the organic waste gas. But different from ordinary adsorbent materials, this material also has a strong oxidative decomposition effect. It can not only decompose the organic matter around the material, but also decompose the organic matter adsorbed into the material, so that the material can be self-cleaning. Under its self-cleaning function, it decomposes pollutants while adsorbing, which is more durable than the simple adsorption principle of activated carbon process, so it can be realized without replacing the filler for a long time. Moreover, the material is made of ceramsite by high temperature sintering, so it is not limited by high temperature and high humidity, and has a wider application range, so it is more convenient to manage than the activated carbon method, and there is no danger of burning. Because it uses the pressure difference generated by other substances in the formula to activate its electrical properties, it is more efficient and economical than photocatalyst (ultraviolet catalytic oxidation) and other oxidation methods, and it does not need to replace the filler; the reaction speed is faster than the biological method.